XL Series

- Single-source, multi-viewing angle technology, expanding the detection range to the top, body and bottom of the bottle, avoiding blind spots

Product Introduction

Suitable for milk powder, canned fruits and vegetables, sauces, medicine granules and other bottles, cans and boxed products in the detection of impurities.

Solving the problem of high cost and difficulty of detecting food after packaging.

Application Field

Package Food: Dairy Product, Bottle and Canned Food, Convenience Food

Product Specificities

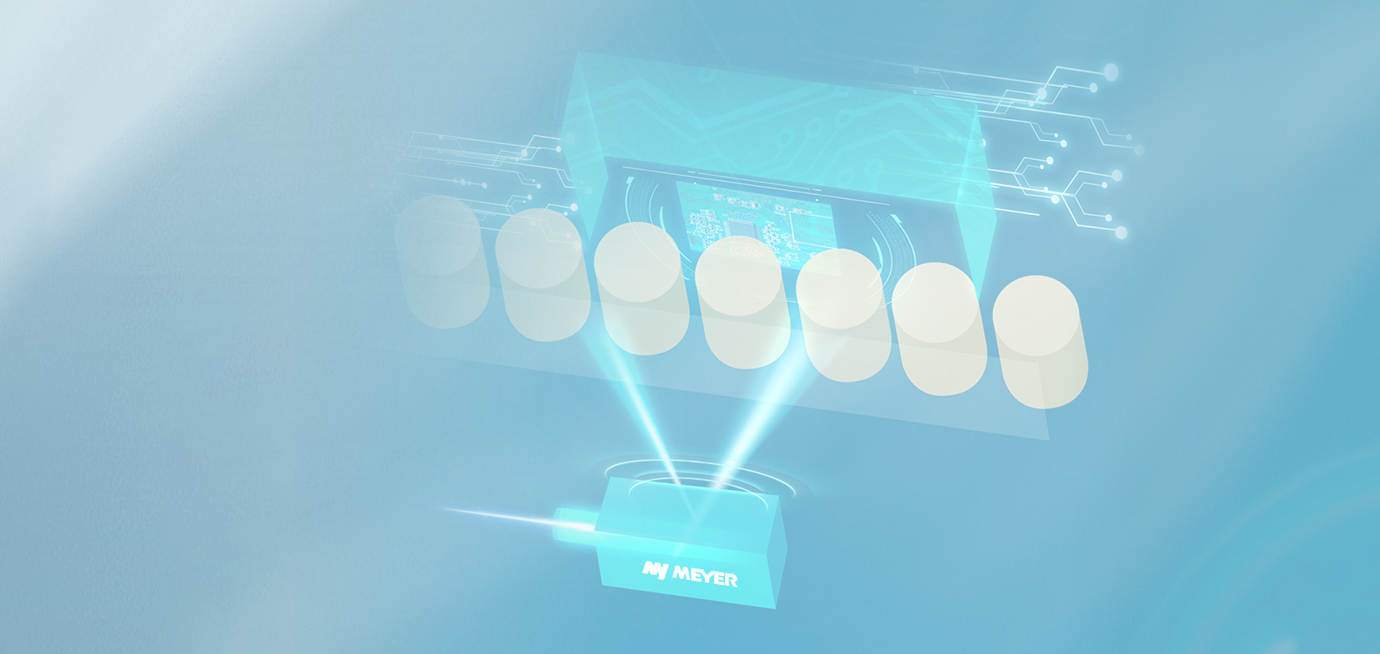

Single-Source Multi-View Angle Technology

Breaking through the technical bottleneck of undetectable impurities at the bottom of bottles and cans, expanding the detection range to the top, body and bottom of the bottle, avoiding blind spots, imaging more comprehensive.

Additional Features

X-Ray Imaging Technology: Using the international advanced beryllium window source, the imaging is clearer, and foreign objects with similar density can be easily identified.

Simple Interface: Modular UI design makes the operation more simple; built-in learning package that you can easily get training courseware.

Intelligent Alarm: Equipped with visual LED, so that the signal, light, air pressure and other abnormal conditions can be easily detected and solvedc, making the processing process more assured.

Remote Service: PC/mobile control, can provide online after-sales service such as commissioning, physical examination, maintenance guidance.

Specifications

Conveyor belt speed(m/min): 10-60(adjustable)

Conveyor belt width(mm): 170

Size of materials(mm): width≤150, height≤240

Configuration(mm)(L*W*H): 3000X1237X2104

Service environment: Ambient temperature 0-40℃, relative humidity 30-90% No condensation, no freezing, upheaval

Sensitivity(mm): SUS ball≥0.3, SUS wire≥0.2X2, Ceramic ball≥1.0, Glass ball≥1.0

Net weight(kg): 300

Removal device: Pneumatic push plate rejection

Air pressure: 0.6-0.8MPa

X-ray output: 350W, Max80kV/8.0mA

Interface: 17 inch LCD touch screen

Protection Level: IP65